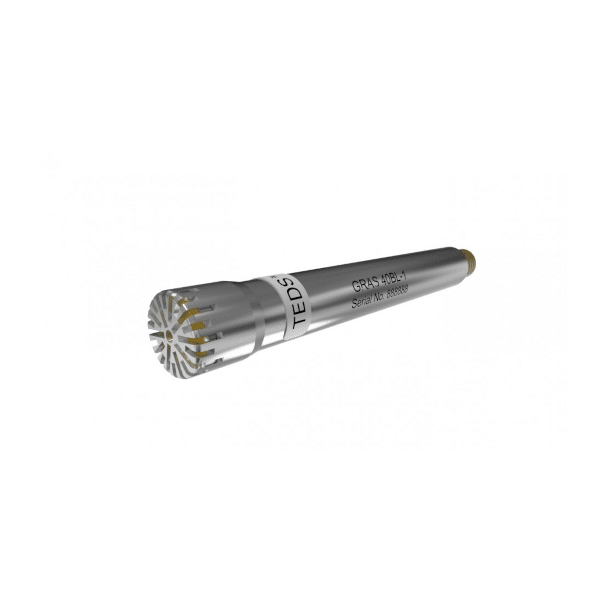

GRAS 46BL-1 1/4" CCP Pressure Standard Microphone Set, High Sensitivity

19.912,50 incl. VAT

Use our chat for personal support or contact us via +45 31 33 18 19 or salg@GOmeasure.dk

- Freq range: 4 Hz to 20 kHz

- Dyn range: 24 dB(A) to 146 dB

- Sensitivity: 20 mV/Pa

Discover the possibilities

More information

Description

GRAS 46BL-1 1/4" CCP Pressure Standard Microphone Set, High Sensitivity

Why is high-frequency measurement needed?

Acoustic quality requirements for telecom, audio, PCs and tablets are ever increasing, with a constant trend towards tighter production tolerances and the need to include higher frequencies in testing. The physical properties of smaller microphones not only make them a great solution for meeting those requirements and minimizing error in the data measured on the production line, they are more easily placed on the lines, where a small footprint is critical—smaller microphones can be fitted in smaller test setups.Is smaller better?

There is no magic microphone that is perfect for all possible measurement scenarios, but the actual physical size of ¼″ microphones provides many benefits. The size-related properties reduce the pressure build-up effect on the diaphragm, but also significantly minimize error when when the sound wave is not 0° incidence and can inherently enable measurements at higher-frequency ranges and pressure levels. And when accounting for real-world conditions and measuring where there are many reflections and disturbances, such as in-cabin, the physical advantages of a ¼″ microphone can greatly increase accuracy and simplify post-processing data. For example, at 20 kHz, a ½″ free-field (FF) mic underrepresents the sound power of a 90° incidence wave by ca. 10 dB—a ¼″ FF mic, only by approx. 3 dB. This results in more accurate data in environments with random angles of incidence where corrections are difficult or impossible to estimate.Benefits at a glance

- Reduced influence of the angle of incidence.

- Well-suited for high-frequency measurements.

- Minimal footprint for easy placement on a production line.

- Small diaphragms enable the possibility for testing miniature microphones, such as MEMS.

- Reduced influence on measurement environment due to their small size.

- Lowest noise in the industry for high sensitivity, pressure and free field.

- Enables extreme SPL measurement.

- Competitive pricing.

GRAS 46BL-1 CCP Pressure Standard Microphone Set, High Sensitivity

Through close cooperation with our customers, we know that data-safety is highly important because the costs related to unsuited and unreliable sensors may determine whether your project turns into a success or not.GRAS 46BL-1 is an updated version of GRAS 46BL. Concerning the physical considerations of incorporating or replacing GRAS 46BL in existing setups, GRAS 46BL-1 is a one-to-one match regarding performance, dimensions, and price; however, GRAS46BL-1 has a slightly lower noise floor and a 180° phase shift.

For our users, data safety translates directly into requests for easier microphone selection, simple system configuration, and reduction of measurement errors. To meet these requirements, we invented the microphone set concept. It is simple, reliable, and robust and consists of a microphone cartridge and preamplifier combination, which is calibrated as one unit.

This eliminates errors because there is only one sensitivity value to account for and the risk of contaminating the interface is eliminated. Combine this with our unique and proven design and you have the most reliable measurement microphone sets available in the industry today.

Typical applications and use

GRAS 46BL-1 is ideally suited for production line testing of portable communication devices, such as cell phones, laptop computers, tablets, GPS receivers, and similar devices using microspeakers.It is also well suited for general acoustic measurements when high sensitivity and low noise are required. In particular, due to the properties of small microphones (visit the blog post for more information), GRAS 46BL-1 excels at in-cabin testing and measurement, and fulfills the recommendations of the Audio Engineering Society (AES) for infotainment system evaluation.

In-car acoustic measurements.

The AES Technical Committee on Automotive Audio [TC-AA] has developed some very useful guidelines for In-car Acoustic measurements in a whitepaper from 2023.This paper is focused on measurements with microphones in the driver and passenger seat, both on methods and instrumentation.

The RA0399 holder is specially designed to meet the specification in the whitepaper.Together with the GRAS 46BC high sensitive microphone ( or the high sensitive pressure microphone GRAS 46BL-1)set, it fulfills the complete test demands in the white paper.

Find more information on the RA0399 array and the typical use according to EAS whitepaper in this instruction manual: RA0399 H-shaped holder for 6-unit microphone array

Regarding temperature range, see the specifications. If measurement at higher temperatures is required, a GRAS probe microphone, where the microphone and preamplifier can be isolated from the hot source.

NOTES:

- To achieve optimal performances GRAS 46BL-1 must be powered on for at least two minutes before starting a measurement.

- Unlike other CCP microphones, a positive pressure on the GRAS 46BL-1 diaphragm generates a negative output voltage.

Compatibility

To perform as specified, the GRAS 46BL-1 microphone set requires a constant current input module that can deliver 4 mA and 24 V unloaded CCP voltage supply. If the constant current supply is lower, the capability of driving long cables is reduced, and consequently, the upper frequency is reduced. If the voltage supply is lower, it will influence the upper dynamic range.The microphone set is terminated with a 10/32 Microdot female connector. Ready-to-use coax cable assemblies of various types and lengths are available in standard as well as customized lengths.

The GRAS 46BL-1 is IEEE 1451.4 TEDS v. 1.0 compliant. If your measurement platform supports Transducer Electronic Data Sheets, you will be able to read and write data like properties and calibration data.

Calibration

GRAS 46BL-1 has a diaphragm that is slightly larger in diameter than is standard for ¼″ microphones. This does not affect sensitivity calibration, but for frequency calibration using an electrostatic actuator, you need a RA0236 Adapter.

System verification

The functionality of TEDS is very useful to determine which microphone is connected to which input channel. However, it is not a check of whether the microphone is within specifications or not. For daily verification and check of your measurement setup, we therefore recommend using a sound source like the GRAS 42AG Sound Calibrator.For sensitivity calibration in a lab, we recommend using a reference sound source like the GRAS 42AP Intelligent Pistonphone.

Calibration

When leaving the factory, all GRAS microphones have been calibrated in a controlled laboratory environment using traceable calibration equipment. Depending on the use, measurement environment, and internal quality control programs we recommend that the microphone is recalibrated at least once a year.We offer two kinds of calibration as an optional after-sales service: GRAS Traceable Calibration and GRAS Accredited Calibration.

GRAS Traceable Calibration is a traceable calibration performed by trained personnel under controlled conditions according to established procedures and standards. This is identical to the rigorous calibration that all GRAS microphones are subjected to as an integral part of our quality assurance.

GRAS Accredited Calibration is performed by the GRAS Accredited Calibration Laboratory that has been accredited in accordance with ISO 17025 by DANAK, the Danish Accreditation Fund.

If you want a new microphone set delivered with an accredited calibration instead of the default factory calibration, specify this when ordering.

Learn more at gras/calib.

Quality and warranty

GRAS microphone sets are made of components from our proven standard portfolio and are all manufactured of high-quality material and branded parts that were chosen and processed to ensure life-long stability and robustness.All parts are manufactured and assembled at the factory in Denmark by skilled and dedicated operators in a verified clean-room environment. The microphone diaphragm, body, and unique protection grid are made of high-grade stainless steel and make the microphone set resistant to physical damage as well as corrosion caused by aggressive air or gasses.

This, together with the enforced gold-plated microphone terminal, guarantees a highly reliable connection. Thanks to the high quality, our warranty against defective materials and workmanship is five years.

Service

Should you by mistake damage the diaphragm on a GRAS microphone we will in most cases be able to exchange it at a very reasonable cost and short turn-around time. This not only protects your investment but also meets your quality assurance department since you do not have to worry about new serial numbers etc.For more information: GRAS

Click here for related products: Measurement Microphone Sets

Specifications

Documents

GRAS 46BG-FV 1/4" CCP Pressure Front Vented Microphone Set, High Pressure

Datasheet:

GRAS 46BL-1 DatasheetOptions

Video

GRAS 46BL-1 1/4" CCP Pressure Standard Microphone Set, High Sensitivity

Why is high-frequency measurement needed?

Acoustic quality requirements for telecom, audio, PCs and tablets are ever increasing, with a constant trend towards tighter production tolerances and the need to include higher frequencies in testing. The physical properties of smaller microphones not only make them a great solution for meeting those requirements and minimizing error in the data measured on the production line, they are more easily placed on the lines, where a small footprint is critical—smaller microphones can be fitted in smaller test setups.Is smaller better?

There is no magic microphone that is perfect for all possible measurement scenarios, but the actual physical size of ¼″ microphones provides many benefits. The size-related properties reduce the pressure build-up effect on the diaphragm, but also significantly minimize error when when the sound wave is not 0° incidence and can inherently enable measurements at higher-frequency ranges and pressure levels. And when accounting for real-world conditions and measuring where there are many reflections and disturbances, such as in-cabin, the physical advantages of a ¼″ microphone can greatly increase accuracy and simplify post-processing data. For example, at 20 kHz, a ½″ free-field (FF) mic underrepresents the sound power of a 90° incidence wave by ca. 10 dB—a ¼″ FF mic, only by approx. 3 dB. This results in more accurate data in environments with random angles of incidence where corrections are difficult or impossible to estimate.Benefits at a glance

- Reduced influence of the angle of incidence.

- Well-suited for high-frequency measurements.

- Minimal footprint for easy placement on a production line.

- Small diaphragms enable the possibility for testing miniature microphones, such as MEMS.

- Reduced influence on measurement environment due to their small size.

- Lowest noise in the industry for high sensitivity, pressure and free field.

- Enables extreme SPL measurement.

- Competitive pricing.

GRAS 46BL-1 CCP Pressure Standard Microphone Set, High Sensitivity

Through close cooperation with our customers, we know that data-safety is highly important because the costs related to unsuited and unreliable sensors may determine whether your project turns into a success or not.GRAS 46BL-1 is an updated version of GRAS 46BL. Concerning the physical considerations of incorporating or replacing GRAS 46BL in existing setups, GRAS 46BL-1 is a one-to-one match regarding performance, dimensions, and price; however, GRAS46BL-1 has a slightly lower noise floor and a 180° phase shift.

For our users, data safety translates directly into requests for easier microphone selection, simple system configuration, and reduction of measurement errors. To meet these requirements, we invented the microphone set concept. It is simple, reliable, and robust and consists of a microphone cartridge and preamplifier combination, which is calibrated as one unit.

This eliminates errors because there is only one sensitivity value to account for and the risk of contaminating the interface is eliminated. Combine this with our unique and proven design and you have the most reliable measurement microphone sets available in the industry today.

Typical applications and use

GRAS 46BL-1 is ideally suited for production line testing of portable communication devices, such as cell phones, laptop computers, tablets, GPS receivers, and similar devices using microspeakers.It is also well suited for general acoustic measurements when high sensitivity and low noise are required. In particular, due to the properties of small microphones (visit the blog post for more information), GRAS 46BL-1 excels at in-cabin testing and measurement, and fulfills the recommendations of the Audio Engineering Society (AES) for infotainment system evaluation.

In-car acoustic measurements.

The AES Technical Committee on Automotive Audio [TC-AA] has developed some very useful guidelines for In-car Acoustic measurements in a whitepaper from 2023.This paper is focused on measurements with microphones in the driver and passenger seat, both on methods and instrumentation.

The RA0399 holder is specially designed to meet the specification in the whitepaper.Together with the GRAS 46BC high sensitive microphone ( or the high sensitive pressure microphone GRAS 46BL-1)set, it fulfills the complete test demands in the white paper.

Find more information on the RA0399 array and the typical use according to EAS whitepaper in this instruction manual: RA0399 H-shaped holder for 6-unit microphone array

Regarding temperature range, see the specifications. If measurement at higher temperatures is required, a GRAS probe microphone, where the microphone and preamplifier can be isolated from the hot source.

NOTES:

- To achieve optimal performances GRAS 46BL-1 must be powered on for at least two minutes before starting a measurement.

- Unlike other CCP microphones, a positive pressure on the GRAS 46BL-1 diaphragm generates a negative output voltage.

Compatibility

To perform as specified, the GRAS 46BL-1 microphone set requires a constant current input module that can deliver 4 mA and 24 V unloaded CCP voltage supply. If the constant current supply is lower, the capability of driving long cables is reduced, and consequently, the upper frequency is reduced. If the voltage supply is lower, it will influence the upper dynamic range.The microphone set is terminated with a 10/32 Microdot female connector. Ready-to-use coax cable assemblies of various types and lengths are available in standard as well as customized lengths.

The GRAS 46BL-1 is IEEE 1451.4 TEDS v. 1.0 compliant. If your measurement platform supports Transducer Electronic Data Sheets, you will be able to read and write data like properties and calibration data.

Calibration

GRAS 46BL-1 has a diaphragm that is slightly larger in diameter than is standard for ¼″ microphones. This does not affect sensitivity calibration, but for frequency calibration using an electrostatic actuator, you need a RA0236 Adapter.

System verification

The functionality of TEDS is very useful to determine which microphone is connected to which input channel. However, it is not a check of whether the microphone is within specifications or not. For daily verification and check of your measurement setup, we therefore recommend using a sound source like the GRAS 42AG Sound Calibrator.For sensitivity calibration in a lab, we recommend using a reference sound source like the GRAS 42AP Intelligent Pistonphone.

Calibration

When leaving the factory, all GRAS microphones have been calibrated in a controlled laboratory environment using traceable calibration equipment. Depending on the use, measurement environment, and internal quality control programs we recommend that the microphone is recalibrated at least once a year.We offer two kinds of calibration as an optional after-sales service: GRAS Traceable Calibration and GRAS Accredited Calibration.

GRAS Traceable Calibration is a traceable calibration performed by trained personnel under controlled conditions according to established procedures and standards. This is identical to the rigorous calibration that all GRAS microphones are subjected to as an integral part of our quality assurance.

GRAS Accredited Calibration is performed by the GRAS Accredited Calibration Laboratory that has been accredited in accordance with ISO 17025 by DANAK, the Danish Accreditation Fund.

If you want a new microphone set delivered with an accredited calibration instead of the default factory calibration, specify this when ordering.

Learn more at gras/calib.

Quality and warranty

GRAS microphone sets are made of components from our proven standard portfolio and are all manufactured of high-quality material and branded parts that were chosen and processed to ensure life-long stability and robustness.All parts are manufactured and assembled at the factory in Denmark by skilled and dedicated operators in a verified clean-room environment. The microphone diaphragm, body, and unique protection grid are made of high-grade stainless steel and make the microphone set resistant to physical damage as well as corrosion caused by aggressive air or gasses.

This, together with the enforced gold-plated microphone terminal, guarantees a highly reliable connection. Thanks to the high quality, our warranty against defective materials and workmanship is five years.

Service

Should you by mistake damage the diaphragm on a GRAS microphone we will in most cases be able to exchange it at a very reasonable cost and short turn-around time. This not only protects your investment but also meets your quality assurance department since you do not have to worry about new serial numbers etc.For more information: GRAS

Click here for related products: Measurement Microphone Sets