Wentworth Pegasus Probe

Use our chat for personal support or contact us via +45 31 33 18 19 or salg@GOmeasure.dk

- Integrated wafer height and edge sensor

- Variable contact force adjustment

- Smooth precision positioning

- Ideal for LED production test

- Versatile for a wide variety of other applications

Discover the possibilities

More information

Description

Wentworth Pegasus Probe

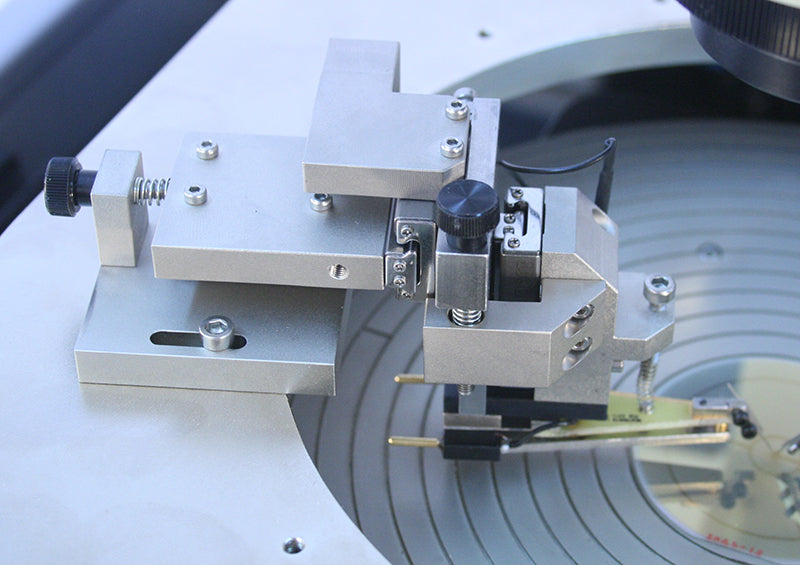

PROBE WITH INTEGRATED HEIGHT AND EDGE SENSOR

The Pegasus™ Probe has an integrated wafer edge and height sensor, combining both functions into one compact unit that quickly secures to a platform designed for multiple Pegasus™ probe units, or a combination of Pegasus™ probes and die inkers.

This makes it the ideal solution for light-emitting diode (LED) production test, replacing device-specific probe cards while enabling high throughput, along with full on-site or delayed inking capabilities.

APPLICATIONS

The Pegasus™ probe designed for a wide range of applications and provides the ideal solution for LED production test. It produces small probe marks, an important advantage when probing for known good die (KGD). Variable contact force adjustment makes it easy to obtain the desired probe mark and throughput.

DESIGN FLEXIBILITY

Pegasus technology enables location and coordinate data to be rapidly acquired. Three fine-pitched controls control the radial, tangential and height adjustment of the Pegasus™ probe. The probe head can be removed in situ to enable simple probe needle replacement, without the need for adhesives or special tools.

Adjustable probes are easily positioned for correct pad spacing, or for different spacing between pads and different device sizes. The sensor function allows for the probing of partial wafers, as well as wafers that are not perfectly flat, ensuring a good quality scrub mark of consistent size regardless or wafer height deviation.

Specifications

Documents

Wentworth Pegasus Probe

Wentworth Pegasus Probe DatasheetOptions

Video

Wentworth Pegasus Probe

PROBE WITH INTEGRATED HEIGHT AND EDGE SENSOR

The Pegasus™ Probe has an integrated wafer edge and height sensor, combining both functions into one compact unit that quickly secures to a platform designed for multiple Pegasus™ probe units, or a combination of Pegasus™ probes and die inkers.

This makes it the ideal solution for light-emitting diode (LED) production test, replacing device-specific probe cards while enabling high throughput, along with full on-site or delayed inking capabilities.

APPLICATIONS

The Pegasus™ probe designed for a wide range of applications and provides the ideal solution for LED production test. It produces small probe marks, an important advantage when probing for known good die (KGD). Variable contact force adjustment makes it easy to obtain the desired probe mark and throughput.

DESIGN FLEXIBILITY

Pegasus technology enables location and coordinate data to be rapidly acquired. Three fine-pitched controls control the radial, tangential and height adjustment of the Pegasus™ probe. The probe head can be removed in situ to enable simple probe needle replacement, without the need for adhesives or special tools.

Adjustable probes are easily positioned for correct pad spacing, or for different spacing between pads and different device sizes. The sensor function allows for the probing of partial wafers, as well as wafers that are not perfectly flat, ensuring a good quality scrub mark of consistent size regardless or wafer height deviation.