SIEPEL SEA-MML Three Layers Flat Absorber

Use our chat for personal support or contact us via +45 31 33 18 19 or salg@GOmeasure.dk

MAIN CHARACTERISTICS

- Matrix: polyether polyurethane foam with 90% open cells

- Impregnating agents: carbon, binder, fire retardant

- Colours: black, blue, white, green, red (other colours upon request)

- Paint: plastic coated paint for clean room

- Maximum service temperatures: [- 65 ; +160]°C

- Power handling: 0.16 W/cm² max CW

Discover the possibilities

More information

Description

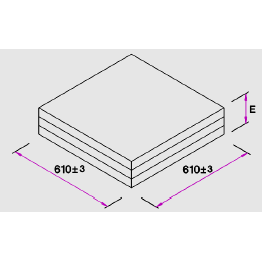

SIEPEL AT Three Layers Flat Absorber

AT consisting in three layers of polyether polyurethane foam with 90% open cells impregnated with a carbon solution, a binder and a fire retardant.AT absorbers are used to cover all metallic surfaces, walls in shielded rooms, masts and antenna bases. They also contribute to the reduction of coupling between antennas. Their high absorption characteristics are obtained with small thicknesses.

COMPLIANCE TO STANDARDS & DIRECTIVES

Fire resistance: NRL 8093 (Test 1, 2, 3), ISO 11925-2, DIN 4102 (class B2).Their raw materials are compliant to RoHS/REACH and free of substances in the current list of Substances of Very High Concern (SVHC) published by the European Chemicals Agency (ECHA)

Both aqueous and plastic paint coating were developed to enable work in ISO 4 (ISO 14644-1 2015) clean room conditions.

METHOD OF USE

Absorbers are flexible and can be cut easily. They are installed thanks to Neoprene glue or Velcro fastening system or auto adhesive tape. Neoprene glue is applied with a brush or a pneumatic pistol to both faces to be glued.Specifications

Documents

SIEPEL AT Three Layers Flat Absorber

THREE LAYERS FLAT ABSORBER AT V8Options

Video

SIEPEL AT Three Layers Flat Absorber

AT consisting in three layers of polyether polyurethane foam with 90% open cells impregnated with a carbon solution, a binder and a fire retardant.AT absorbers are used to cover all metallic surfaces, walls in shielded rooms, masts and antenna bases. They also contribute to the reduction of coupling between antennas. Their high absorption characteristics are obtained with small thicknesses.

COMPLIANCE TO STANDARDS & DIRECTIVES

Fire resistance: NRL 8093 (Test 1, 2, 3), ISO 11925-2, DIN 4102 (class B2).Their raw materials are compliant to RoHS/REACH and free of substances in the current list of Substances of Very High Concern (SVHC) published by the European Chemicals Agency (ECHA)

Both aqueous and plastic paint coating were developed to enable work in ISO 4 (ISO 14644-1 2015) clean room conditions.