SIEPEL Absorber Microwave Pyramidal Absorber SEA-PM

Use our chat for personal support or contact us via +45 31 33 18 19 or salg@GOmeasure.dk

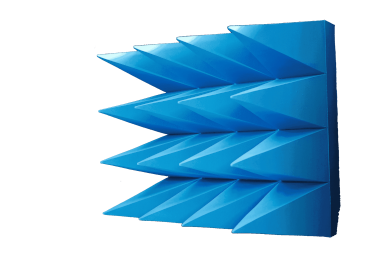

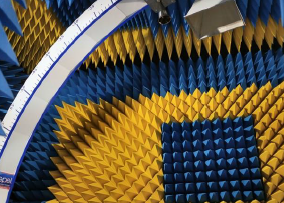

SEA-PM is a range of high performance broadband electro-magnetic absorbers. Each absorber consists of a single block of high tech polyurethane foam, pyramidal-shaped and impregnated with a sophisticated carbon-based aqueous solution. APM absorbers are suitable for broadband applications, and are used to line semi-anechoic and fully anechoic chambers for antenna measurements, Radar Cross Section, compact ranges, telecom, EMC, and military applications

Discover the possibilities

More information

Description

SIEPEL Absorber Microwave Pyramidal Absorber APM

GUARANTEED PERFORMANCES

These reflectivity performances are exceptional; the values are guaranteed for 20 years. These values are the fruit of extensive experience in electromagnetic absorber manufacturing. The reflectivity performances of our absorbers are factory checked, using cutting edge broadband equipment (14 m long coaxial line 1.83 x 1.83 m section, optimised design fully anechoic chamber, Vector Network Analyzers). In addition, we offer to take care of the reflectivity measurements in our factory with SIEPEL engineers, for the customer.The percentage of open cells within the foam absorber material is of utmost importance. APM pyramidal absorbers are made from high tech polyurethane foam, with 90% open cells. This configuration allows a far better impregnation of the carbon solution, and therefore an incomparable distribution of the carbon load through the absorber. The carbon is fixed through the use of a polymerised acrylic binder. All these features lead to unique homogeneity and accurate control of electromagnetic parameters (complex permittivity ε*).

INSTALLATION/DISMANTLING

APM pyramidal absorbers can be easily installed in shielded rooms or on any clean and flat surface using NEOPRENE contact glue, to be applied on both sides to be glued.NUMERICAL SIMULATION

SIEPEL R & D engineers work with state-of-the-art electromagnetic numerical simulation software, in order to continuously optimize both the shape and impregnation agents of the absorbers, over broad frequency ranges.UNIQUE PLASTIC PAINT

SIEPEL plastic paint coating was developed to optimise carbon binding (no finger marks, and no pollution or carbon dust, enabling work in class clean room conditions), improve aesthetics (brightness) and is excellent ageing.This coating is proposed in whatever colour you want: contact us to customize your chamber with your company’s name or logo.

RF POWER HANDLING

APM pyramidal absorbers are designed to handle a power density up-to 2000W/m2 max CW. For high power applications, SIEPEL have developed a special product range called AHP, with an open honeycomb structure for better heat dissipation (see data sheet: AHP High Power Pyramidal Absorber).Specifications

Documents

SIEPEL Absorber Microwave Pyramidal Absorber APM

MICROWAVE PYRAMIDAL ABSORBER APM V14Options

Video

SIEPEL Absorber Microwave Pyramidal Absorber APM

GUARANTEED PERFORMANCES

These reflectivity performances are exceptional; the values are guaranteed for 20 years. These values are the fruit of extensive experience in electromagnetic absorber manufacturing. The reflectivity performances of our absorbers are factory checked, using cutting edge broadband equipment (14 m long coaxial line 1.83 x 1.83 m section, optimised design fully anechoic chamber, Vector Network Analyzers). In addition, we offer to take care of the reflectivity measurements in our factory with SIEPEL engineers, for the customer.The percentage of open cells within the foam absorber material is of utmost importance. APM pyramidal absorbers are made from high tech polyurethane foam, with 90% open cells. This configuration allows a far better impregnation of the carbon solution, and therefore an incomparable distribution of the carbon load through the absorber. The carbon is fixed through the use of a polymerised acrylic binder. All these features lead to unique homogeneity and accurate control of electromagnetic parameters (complex permittivity ε*).

INSTALLATION/DISMANTLING

APM pyramidal absorbers can be easily installed in shielded rooms or on any clean and flat surface using NEOPRENE contact glue, to be applied on both sides to be glued.NUMERICAL SIMULATION

SIEPEL R & D engineers work with state-of-the-art electromagnetic numerical simulation software, in order to continuously optimize both the shape and impregnation agents of the absorbers, over broad frequency ranges.UNIQUE PLASTIC PAINT

SIEPEL plastic paint coating was developed to optimise carbon binding (no finger marks, and no pollution or carbon dust, enabling work in class clean room conditions), improve aesthetics (brightness) and is excellent ageing.This coating is proposed in whatever colour you want: contact us to customize your chamber with your company’s name or logo.