Boundary Layer Measurements

Aeroacoustics is a branch of acoustics that studies noise generation via either turbulent fluid motion or aerodynamic forces interacting with surfaces.

Aeroacoustics is important in the design of vehicles, aircrafts, wind turbines, buildings and bridges to minimize vibrations and noise.

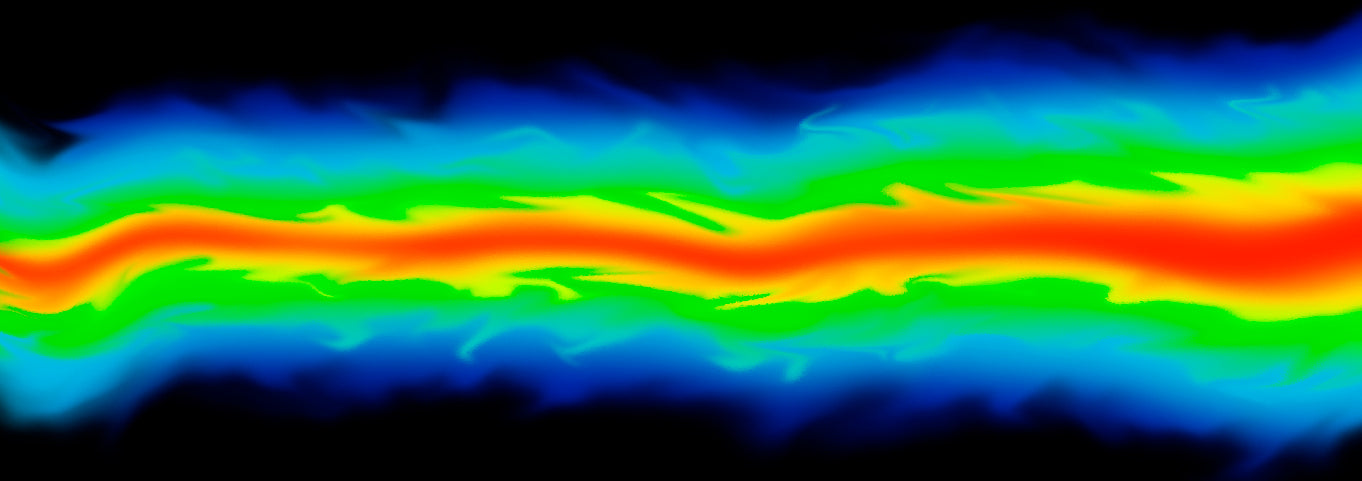

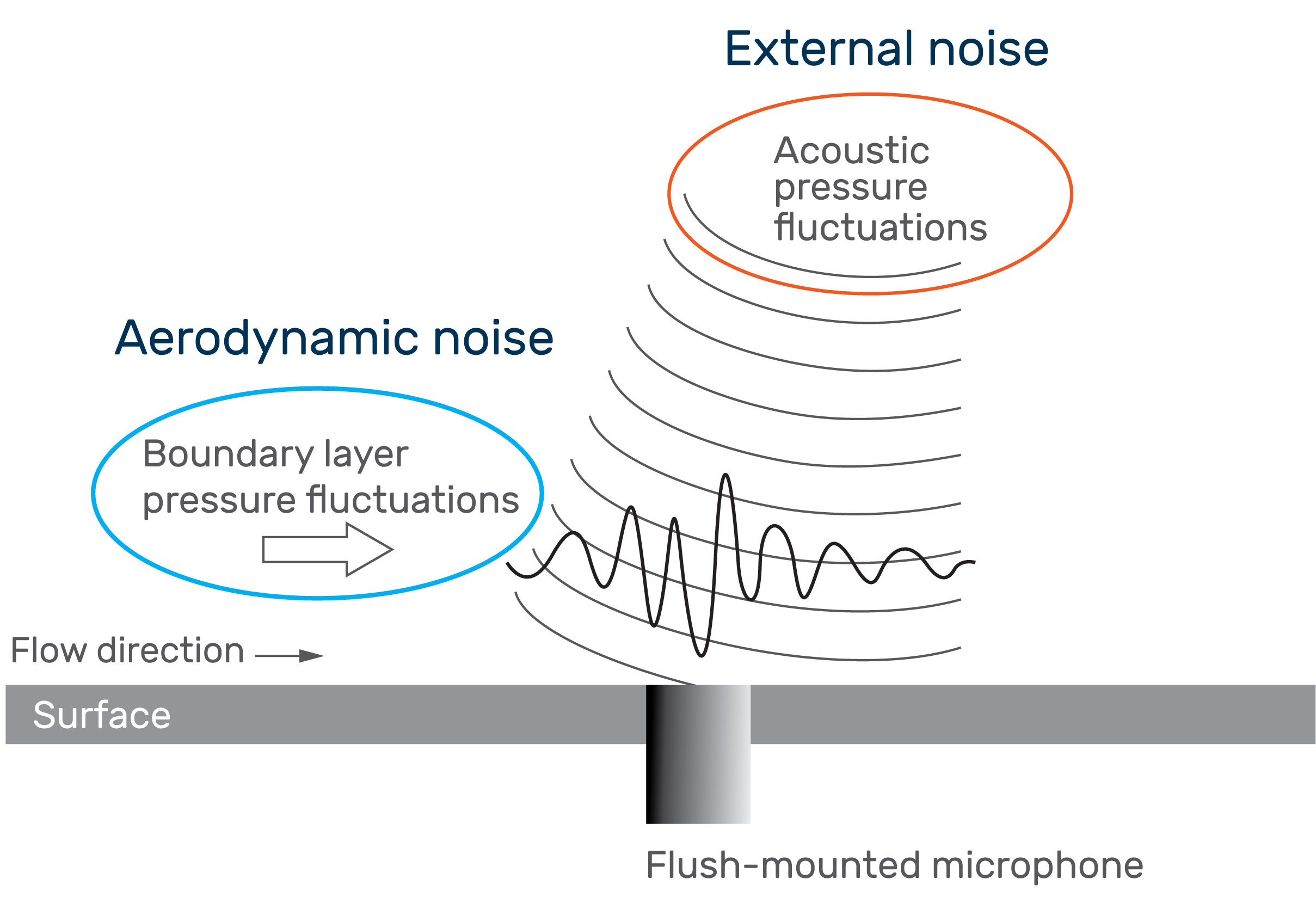

There are two sources of noise, which are important when talking about aeroacoustics – external noise and aerodynamic noise (or pseudo-noise), see below graphics.

The fundamental problems of aeroacoustics is that most test scenarios are expensive and time-consuming and theoretical tests based on calculation software are difficult to simulate realistically. Due to the complexity of boundary layer pressure variations, simulations often require multiple validations and correctional phases.

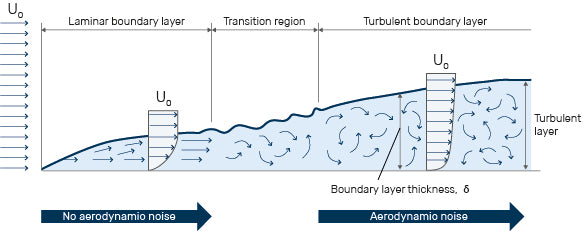

Specifically, it is difficult to quantify and understand the turbulence and flow-induced noise (boundary layer noise) on different vehicles (aircrafts, cars, drones), simulation tools are slow and imprecise due to the stochastic behavior of turbulence, and experimental tests are costly due to the need for anechoic wind tunnels.

Boundary Layer Measurements

The main focus of wind noise testing across industries are measurements in boundary layers. Especialy, in the automotive, aerospace & defense as well as renewables industries, these types of measurements are of increasing importance. The main interest is in separating the acoustic signal from the flow-induced turbulent noise. Purposes span quantifying the amount of sound power radiated from a structure, over sound source localization using an array of microphones to quantifying the turbulent stresses to which a structure is subjected.

Boundary layer theory dictates that measurements must be made exactly on the surface of the structure as the statistics of the flow deviate quickly with increasing distance from the boundary. Moreover, care must be taken not to alter the geometry of the structure as such an action may drastically change the flow. See below illustration.

Due to the complexity of measuring boundary layer pressure variations, it is still very difficult to simulate aeroacoustics and often requires multiple validation and correctional phases. Increasing computational power combined with precision microphones from GRAS allow wind tunnel, on-road and in flight testing. This helps investigate new automotive concepts, verify performance of innovative designs through experimental validations of CFD models, and validate prediction models.

Download ourMeasurement Microphones for Aeroacousticsbrochure.

Discover the new Ultra-Thin Precision (UTP) microphones with an ultra-small form factor, only 1 mm in height.