Acoustic Fatigue

A major problem that all high-speed flying structures face is acoustic fatigue, which is a high-cycle fatigue due to random pressure acoustic loadings that can cause damage to panel structures.

In the case of aircrafts, the design of aerospace vehicles that fly at high speeds under atmospheric conditions are constrained by a limited understanding of flow characteristics over panel structures.

Despite the significant theoretical, numerical and experimental efforts, which have been made in the past, understanding and predicting acoustic fatigue remains largely unresolved.

Furthermore, physical testing of a component is expensive and much of this can only be conducted at the end of the design process. Aeroacoustic engineers will typically try to predict acoustic fatigue by looking at fatigue hotspots of the vehicle and corresponding fatigue life. This combines component loads derived from prototype measurements or multi-body simulations, FE-based stress results and cyclic fatigue material parameters in order to provide feedback on critical fatigue areas and the root cause of fatigue issues.

In the design process, acoustic analysis can also be focused on validating design variants for fatigue life within ever-shorter development cycles, improving the fatigue behavior of welded structures, as well as optimizing durability performance with lightweight and eco-friendly materials.

Solutions

Due to the stochastic behavior of turbulence and flow-induced noise – also referred to as boundary layer noise – it is very difficult to quantify and understand these phenomena. In the development and testing stages of the aerospace, automotive and renewables industries. It has, therefore, been a key focus area for years – but has been hampered by a number of facts.

First of all, experimental tests have proven imprecise due to traditional microphone profile heights. Secondly, the mounting, demounting and remounting of sensors has been a tedious and not very user-friendly process. Finally, simulations and tests in anechoic wind tunnels are costly and most often require careful planning and coordination, making it very time-consuming.

GRAS measurement microphones for boundary layer applications cover UTP microphones, surface microphones and flush-mount microphones – available for surface mounting, “blind window” mounting, destructive mounting or wire-mesh applications.

UTP Microphones – Ultra-Thin Precision Microphones

The GRAS UTP microphones combine the high precision and reliability of GRAS measurement microphones with the need for extremely low-profiled (less than 1 mm) microphones with minimum turbulence influence. With their unique form factor and easy mounting, UTP microphones are specifically designed for in-situ boundary layer testing, when neutral impact and high precision is important. They combine the accuracy of condenser microphones with an extremely small form factor. All LX versions have TEDS.

> High-precision measurement microphones

> Ideal for low-boundary layer testing and confined spaces

> Fast and repeatable mounting with consistent geometry

> Easy in-situ verification

> Wide linear frequency range

> Wide dynamic range

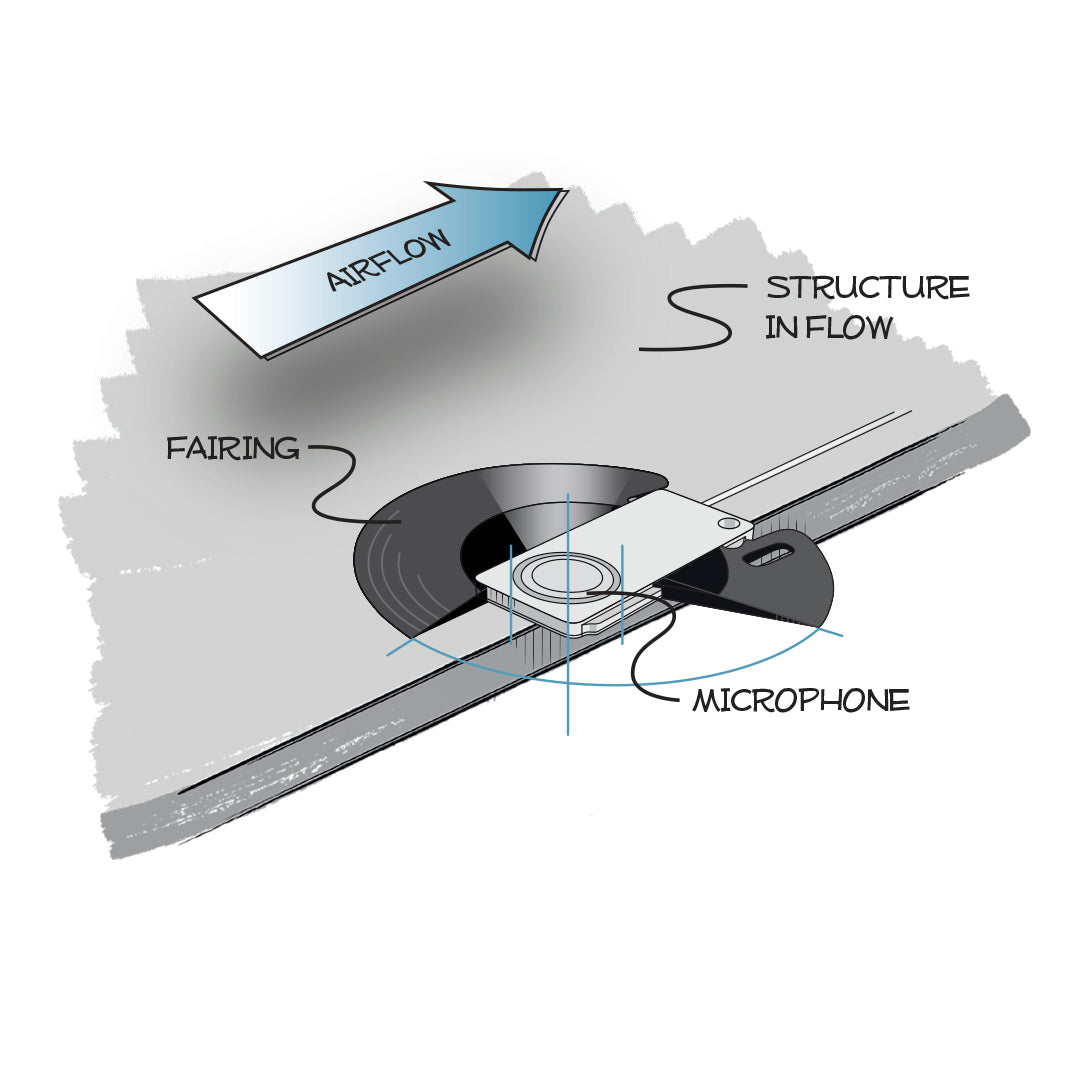

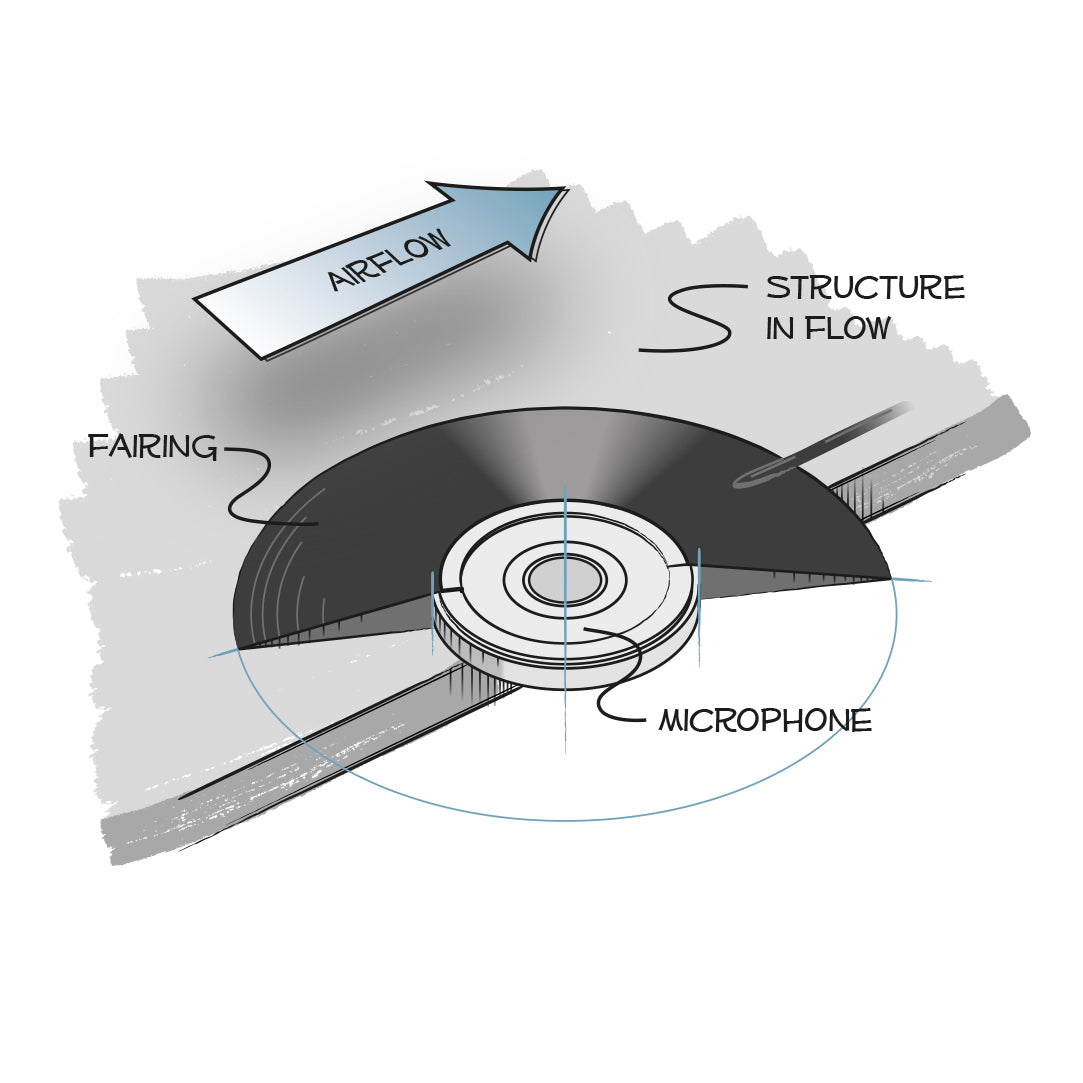

Surface Microphones

The GRAS high-precision surface microphones are designed for in-situ boundary layer testing, where non-invasive mounting is necessary.

They are therefore also well suited for in-flow testing of full-scale objects in wind tunnels.

The height has been kept at 2.5 mm, and a fairing reduces self-generated turbulence.

> High-precision measurement microphones

> Non-invasive mounting and insignificant protrusion

> Integrated preamplifier with plug and measure functionality (TEDS)

> Wide linear frequency range

> Wide dynamic range

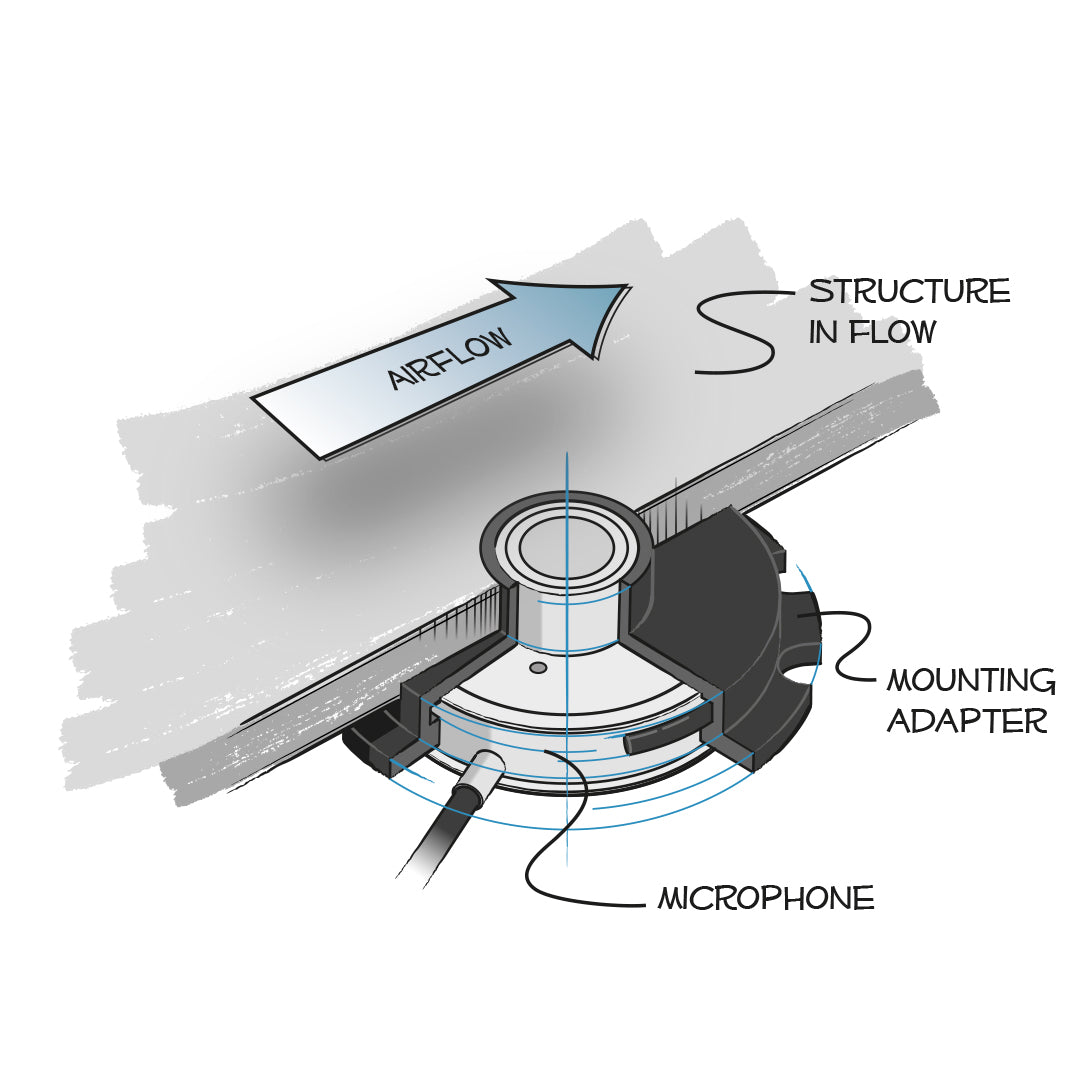

Flush-mount Microphones

This line of acoustic sensors combines the high precision and reliability of GRAS measurement microphones with the need for fitting sensors into very confined spaces and narrow structures.

With an installation height of less than 10 mm, GRAS flush-mount microphones can be integrated into virtually any design without sacrificing aerodynamic properties.

> High-precision measurement microphones

> Very low installation height

> Integrated preamplifier with plug and measure functionality (TEDS)

> Wide linear frequency range

> Wide dynamic range