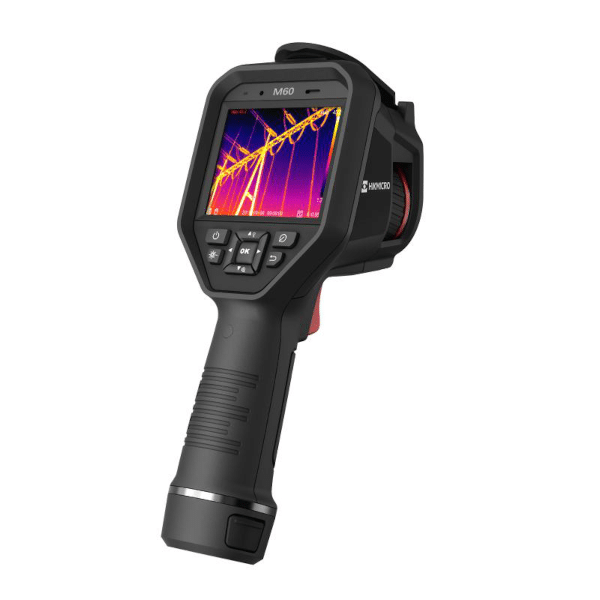

HIKMICRO SuperSCENE+: Opdager mål og identificerer temperaturanomalier

Applikationer

Inspektion af elektriske paneler

Sikring: En enkeltfejl i parallelle sikringsarrangementer går ofte ubemærket hen, hvilket udløser kædereaktioner af overbelastning (NA-produktionsstatistikker: 15% af elektriske brande stammer fra sikringsanomalier).

Terminal: Oxidation/udløsningsinducerede kontaktmodstandsstigninger er stille syndere af udstyrsnedetid (EU Energi Forening: 23% af industrielle nedlukninger relaterer til terminalfejl).

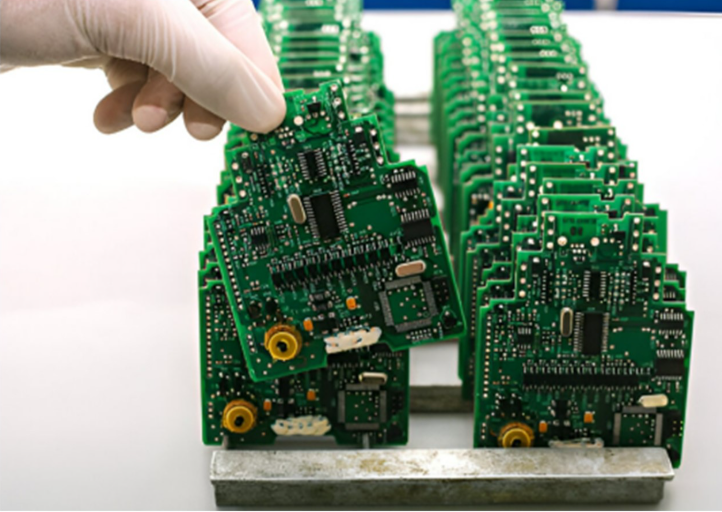

PCB-inspektion

Fejlregistrering:

Identificerer >20 fejlkategorier (åbninger, kortslutninger, pinhuller, resterende kobber) på tværs af multilagskort. Traditionelle flyvende Probe tests overser 30%+ mikrofejl.

Effektivitetsflaskehalse:

- Manuel mikroskopi giver >20% fejlprocenter for under-0,2mm funktioner, hvilket risikerer øjenbelastning.

- Højdensitet PCB-lagscanninger kræver >30min/kort, hvilket forstyrrer produktionscykler.

Introduktion

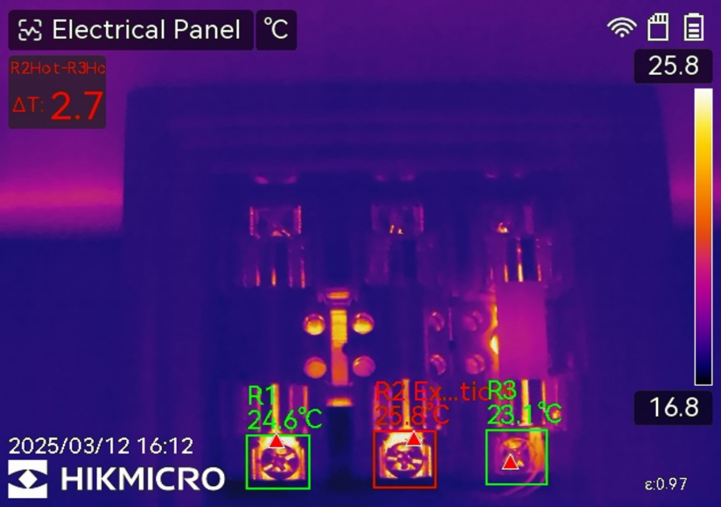

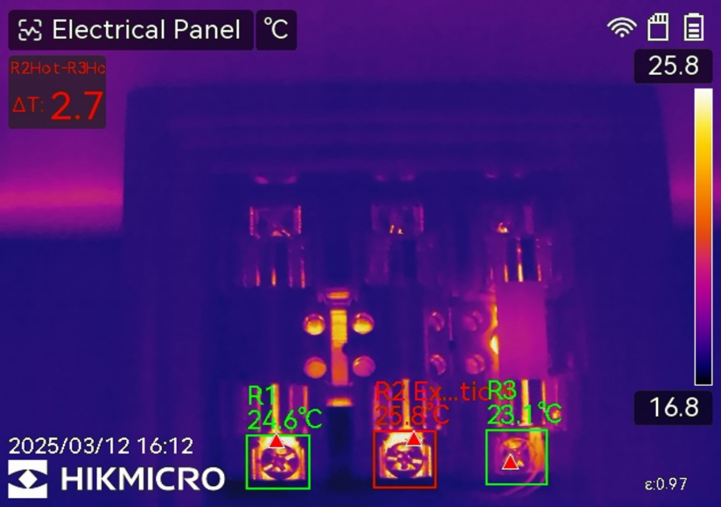

Elektrisk panel - Sikringsinspektion

AI dual-mode detektion: Kombinerer billedgenkendelse og ΔT algoritmer for at præcist lokalisere overbelastede/forringede sikringer via absolutte temperaturalarmer og relative differentielle advarsler.

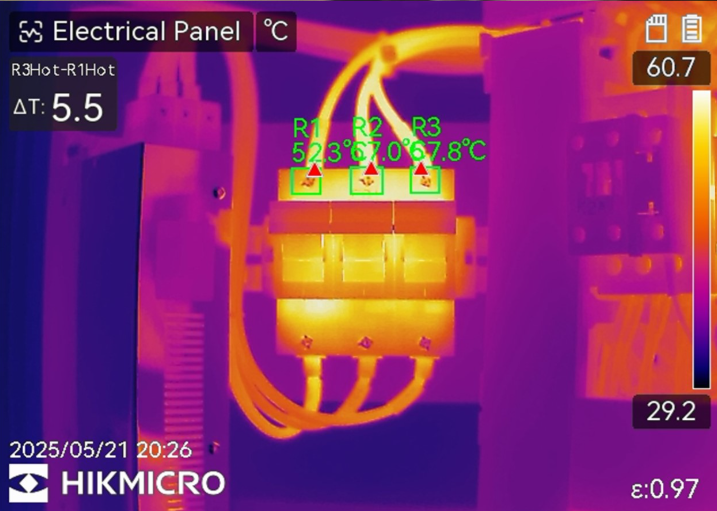

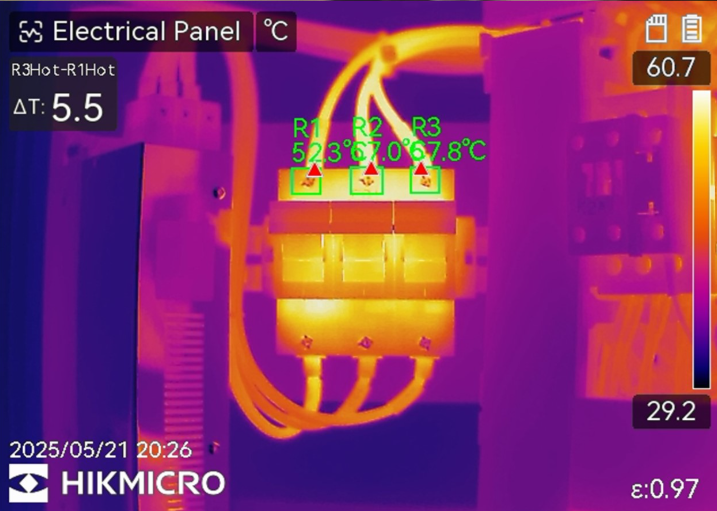

Elektrisk panel - Terminalinspektion

Micro-temperaturføling: Registrerer 0,5°C variationer fra dårlige kontakter ved hjælp af modstand-varme modellering.

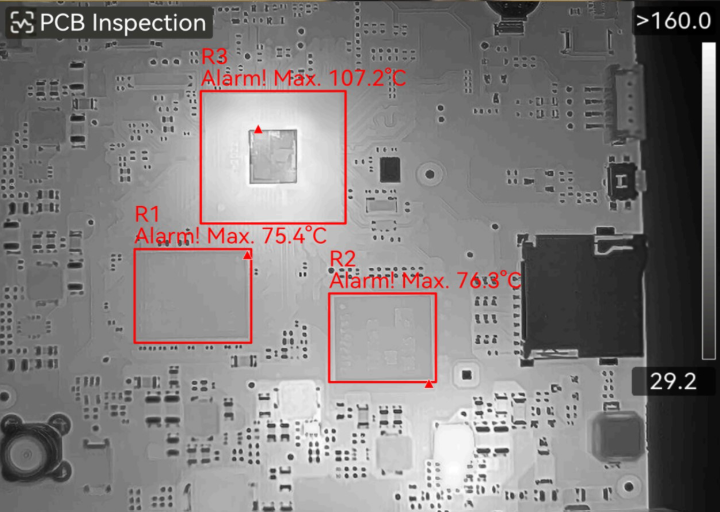

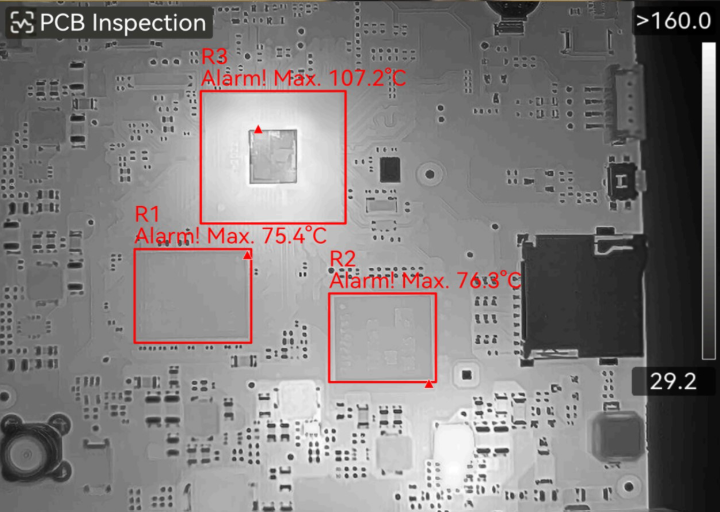

PCB-inspektion

Forudkonfigurerede skabeloner + AI-kalibrering muliggør batchscreening af komponenter (IC'er, modstande/kondensatorer) for at identificere kortslutninger, kolde samlinger og overbelastninger.

Avancerede funktioner:

- 10-zoneskabeloner pr. PCB (f.eks. strømmoduler, signalområder).

- Adskiller normal/unormal opvarmning via kobberlagets termiske ledningsmodeller.

- Opsætnings effektivitet: Reducerer ny PCB-kalibrering fra 30+ minutter til ≤5 minutter gennem skabelon genbrug.

Fordele og fordele ved SuperSCENE+

- Automatisering: Auto-lokaliserer sikringer/terminaler i paneler; PCB batch screening via foruddefinerede skabeloner.

- Forenklet Arbejdsgang: Panelinspektion: Reduceres til 2 trin (tilstandsvalg → scanning) med øjeblikkelige resultater (farvekodede advarsler). PCB-test: Fixture-monterede ét-klik scanninger minimerer menneskelige fejl.

- Reducerer operationel kompleksitet for teknikere, samtidig med at inspektionssikkerhed og resultatpålidelighed forbedres. Afbøder nedetid og optimerer effektiviteten i udstyrslivscyklusstyring.